Umshini wokusika ummese ojikelezayo ozenzakalelayo ophindwe kabili

Umshini wokusika ummese ojikelezayo ozenzakalelayo ophindwe kabili

Mayelana ne-duplex slitter

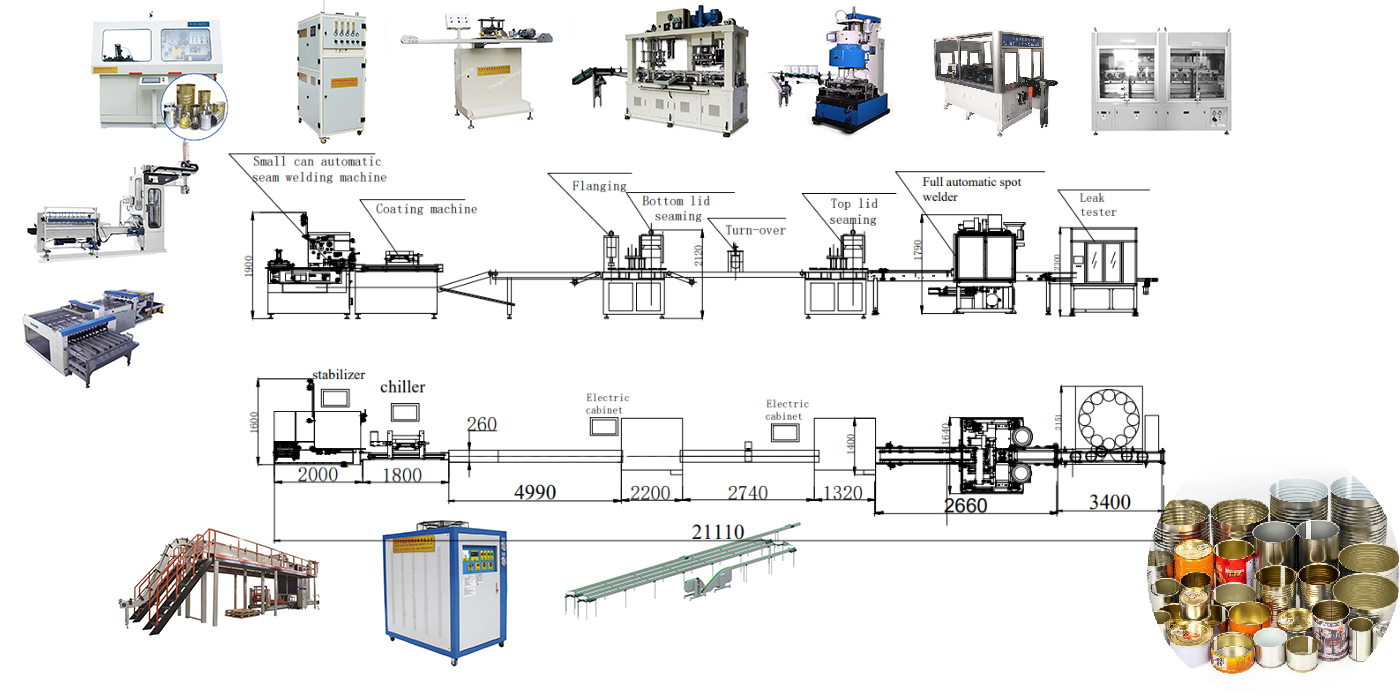

I-duplex slitter ingenye yezingxenye ezibaluleke kakhulu zemishini emgqeni wokukhiqiza amathini anezingcezu ezintathu. Umshini wokusika usetshenziselwa ukusika i-tinplate ibe yizicucu zomzimba wethini ngobukhulu obufanele. I-duplex slitter yethu iyikhwalithi ephezulu futhi iyisisombululo esifanele sefektri yakho yokupakisha insimbi.

Yenzelwe ngqo amafektri okudla okusemathinini kanye nezitshalo zokukhiqiza amathini angenalutho. Ifanele futhi ukusika insimbi ibe ngosayizi ofanayo kwezinye izimboni, futhi ingahlangabezana nezidingo ezidingekayo zomshini wokushisela omelana nesivinini esikhulu.

I-slitter ine-feeder, i-shear, ibhokisi lokulawula likagesi, i-vacuum pump, i-loader kanye ne-sharpener. I-slitter enemisebenzi eminingi iyakwazi ukuguquguquka lapho ingaphakela khona ngokuzenzakalelayo, iqonde phezulu, iqonde phezulu ngokuzenzakalelayo, ithola i-duplex kanye nokubala i-electromagnetism.

Ngamafuphi, i-automatic duplex slitter isebenza kanje:

1. Ukuphakelwa Kwamashidi Okuzenzakalelayo

2. Ukusika Okuqondile, Ukuguqula kanye nokubeka, Ukusika Okuvundlile

3. Ukuqoqa nokubeka izinto ndawonye

Ziqinile kakhulu, zenza kube lula ukulungisa amafomethi ahlukene angenalutho futhi ziqinisekisa ukunemba okuphezulu kakhulu. Uma kukhulunywa ngokuguquguquka, ukunemba, ukuthembeka kanye nesivinini sokukhiqiza, ama-slitter ethu afaneleka kakhulu ekukhiqizeni ithini.

Amapharamitha Obuchwepheshe

| Ubukhulu beshidi | 0.12-0.4mm |

| Ubude beshidi nobubanzi besayizi | 600-1200mm |

| Inani lemichilo yokuqala yokusika | 4 |

| Inani lokusikwa kwesibili | 4 |

| Ububanzi bokuqala bokusika | 160mm-500mm |

| Ububanzi bokusika kwesibili | 75mm-1000mm |

| iphutha losayizi | Ububanzi 0.02 mm |

| Iphutha eliqondile | Ububanzi 0.05 mm |

| iphutha | ≤0.015mm |

| Isivinini sokukhiqiza esizinzile | Amashidi angu-30/umzuzu |

| amandla | Cishe i-12Kw |

| Ukwamukelwa kusekelwe ezindinganisweni ze-iron zebanga lokuqala noma izinto ezilinganayo ze-Baosteel. | |

| Ukunikezwa kwamandla kagesi | Intambo yesihlanu yesigaba sesithathu se-AC (enesisekelo esisebenzayo kanye nesisekelo esivikelayo) |

| I-voltage | 380V |

| I-voltage yesigaba esisodwa | 220V±10% |

| Ibanga lokuvama | 49~50.5Hz |

| Izinga lokushisa | ngaphansi kwama-40°C |

| Umswakama | ngaphansi kuka-80% |

Ulwazi olwengeziwe mayelana ne-single slitter

I-slitter yeshidi le-tinplate iyisiteshi sokuqala somugqa wokwenza amathini.

Isetshenziselwa ukusika ishidi le-tinplate noma ishidi lensimbi engagqwali kanye nezimbobo zomzimba ezinobukhulu obudingekayo noma imichilo yeziphetho zethini. I-duplex slitter noma i-single slitter ziyasebenziseka, zinembile futhi ziqinile.

Ngomshini wokusika owodwa, ulungele ukwahlukanisa nokusika imicu, kanti ngomshini wokusika ophindwe kabili, uwukusika okuvundlile ngokusika okuqondile. Lapho umshini wokusika i-tinplate usebenza, umsiki ongaphezulu kanye nomsiki ongezansi zigoqeka zombili izinhlangothi zeshidi lensimbi eliphrintiwe nelicwebezelwe nge-lacquer, inani labasiki bokusika lisekelwe enanini lemicu kanye nefomethi engenalutho. Ibanga phakathi komsiki ngamunye kulula futhi kuyashesha ukulilungisa, ngakho-ke uhlobo lomshini wokusika i-tinplate lubizwa nangokuthi umshini wokusika i-gang noma umshini wokusika i-gang. Umsiki we-carbide uyatholakala kumenzi we-can.

Ngaphambi komshini wokusika i-duplex noma umshini wokusika owodwa, i-othomathikhi yeshidi ifakelwe ukumunca nokuhambisa i-tinplate ngokumunca idiski ngohlelo lwe-pneumatic kanye nedivayisi yokuthola amashidi amabili. Ngemva kokugunda, umqoqi kanye ne-stacker bangakhipha ngokuzenzakalelayo, futhi ukudluliselwa phakathi kwe-slitter kanye ne-canbody welder nakho kuyatholakala.

Isivinini esiphezulu kanye nezinto ezincane zidinga ukunemba okuphezulu kanye nezindawo ezikhazimulayo. Amashidi aqondiswa njalo. Ama-Conveyor aqinisekisa ukuthi ishidi, umugqa kanye nokuthuthwa okungenalutho kubushelelezi futhi kuphephile. I-slitter eyodwa ingaqedwa ngokusebenza kwesibili kokusika; ngakho-ke ukutshalwa kwezimali ku-slitter eyodwa kuwukutshalwa kwezimali okubaluleke kakhulu uma umkhiqizo wokukhiqiza we-canbody uhlelwe ukuthi wande. Kulula ukuyinakekela nokuyisebenza. Yemichilo yokusika noma nje ukunquma amashidi. Iyatholakala kwi-tinplate noma kumashidi e-aluminium.