Iqhaza Lomshini Wokushisela Okuthuthukisiwe kanye Nomshini Wokuhlibilika Ekwenziweni Kwe-Tin Can

Ekupakishweni kokudla neziphuzo, amathini kathayela ayaqhubeka nokuba yisisekelo ngenxa yokuqina kwawo, ukuphumelela kwezindleko, kanye nekhono lokulondoloza okuqukethwe. Inqubo yokukhiqiza la mathini, nokho, iye yashintsha kakhulu eminyakeni edlule, nokuthuthuka kwezobuchwepheshe okwenza ukukhiqizwa kusebenze kahle futhi kunembile. Enkabeni yokukhiqiza amathini esimanje kukhona izingcezu zemishini ezenzakalelayo njengemishini yokushisela i-canplate, imimese yokusika ye-tinplate, nemishini yokusika ezenzakalelayo, eqinisekisa umkhiqizo oqediwe wekhwalithi ephezulu.

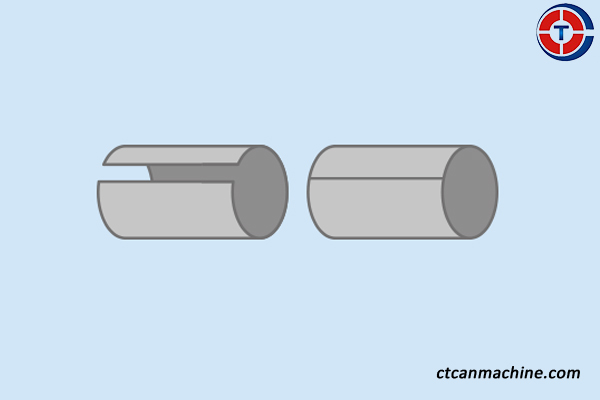

Enye yentuthuko ebaluleke kakhulu kulayini wokukhiqiza we-tin can umshini wokushisela othomathikhi we-can body. Le mishini idlala indima ebalulekile ekuhlanganiseni umzimba we-cylindrical wekani ngokushisela ama-seams ensimbi, ngokuvamile kusetshenziswa izinto ezifana ne-tinplate, i-iron plate, i-chrome plate, i-galvanized plate, nensimbi engagqwali. Imishini yokushisela yesimanje evela kubakhiqizi abafana ne-Changtai Intelligent yakhelwe isivinini nokunemba, yandisa okokusebenza kanye nokunciphisa amathuba okuba namaphutha. Le mishini ihlelelwe ukushisela ama-seams ngokunemba okuphezulu, okubalulekile ekuqinisekiseni ubuqotho besakhiwo sethini.

izinzuzo ezibalulekile

Iothomathikhi can body Welding umshiniinikeza izinzuzo ezibalulekile ezimbalwa eziyenza ibe ucezu lwesisetshenziswa esibalulekile ekukhiqizeni amathini esimanje:

● Ukwenyuka Kwesivinini Sokukhiqiza: Imishini yokushisela okuzenzakalelayo inciphisa kakhulu isikhathi esidingekayo sokujoyina amashidi ensimbi, okwandisa isivinini senqubo yokukhiqiza. Lokhu kwenza abakhiqizi bakwazi ukukhiqiza inqwaba yamathini ngesikhathi esifushane, bathuthukise ukusebenza kahle futhi bahlangabezane nesidingo esikhulu.

● Ukunemba Okuphezulu Nokungaguquguquki: Le mishini iklanyelwe ukushisela okunembile kwemithungo yensimbi, iqinisekisa ukushiselwa okungaguquguquki nokufana okufanayo kuwo wonke amathini. Ukunemba kwemishini yokushisela okuzenzakalelayo kusiza ekuqedeni amaphutha njengama-seams abuthakathaka noma angalingani, angahle abeke engcupheni ubuqotho besakhiwo samathini.

● Izindleko Ezincishisiwe Zabasebenzi: Njengoba inqubo izenzekelayo, isidingo somsebenzi wezandla sincipha kakhulu. Lokhu akunciphisi nje kuphela izindleko zabasebenzi kodwa futhi kunciphisa amaphutha abantu, okuholela kwikhwalithi yokukhiqiza engaguquki. Abaqhubi badinga kuphela ukuqapha umshini, okunciphisa ingozi yamaphutha nezingozi.

● Ukusebenza Kwamandla: Imishini yokushisela yesimanje ngokuvamile iklanywa ngezici zokonga amandla ezithuthukisa ukusetshenziswa kwamandla ngesikhathi senqubo yokushisela. Lokhu kunciphisa izindleko zokusebenza futhi kufaka isandla emikhubeni yokukhiqiza esimeme kakhudlwana.

● Ukulawulwa Kwekhwalithi Okuthuthukisiwe: Ngezici ezithuthukisiwe ezifana nezinhlelo zokuhlola ithungo ezizenzakalelayo namasistimu okulawula, le mishini ingathola amaphutha ngesikhathi sokukhiqiza, iqinisekisa ukuthi amathini kuphela ahlangabezana nezindinganiso zekhwalithi adlulela esigabeni esilandelayo senqubo. Lokhu kuqapha okuqhubekayo kuthuthukisa ikhwalithi isiyonke yomkhiqizo oqediwe.

● Izindleko Zokulungisa Okuphansi: Imishini eminingi yokushisela okuzenzakalelayo yakhiwe ngezinto ezihlala isikhathi eside, zekhwalithi ephezulu ezidinga ukunakekelwa okungavamile uma kuqhathaniswa namamodeli amadala, asebenza ngezandla. Ukuxilongwa okuzenzakalelayo okujwayelekile nakho kusiza ukuhlonza izinkinga ezingaba khona ngaphambi kokuthi ziholele esikhathini sokuphumula noma ukulungisa okubizayo.

● Ukuhlanganiswa Nezinye Izisetshenziswa: Le mishini yokushisela ingahlanganiswa ngaphandle komthungo emugqeni wokukhiqiza ozishintshayo, osebenza ngokuhlanganyela neminye imishini efana nemishini yokusika, imishini yokunquma, nemishini yokumboza. Lokhu kudala inqubo yokukhiqiza ehlelekile, ephumelelayo enciphisa izingqinamba futhi ithuthukise ukuphuma.

● Ukuguquguquka Kokwenza Ngokwezifiso: Imishini eminingi yokushisela amathini e-othomathikhi ingalungiswa ukuze ikwazi ukuthwala amasayizi ahlukene kanye nokucaciswa kwawo. Lokhu kuvumelana nezimo kwenza kube lula ukwenza ngendlela oyifisayo ukuqhutshwa kokukhiqiza ukuze kuhlangatshezwane nezidingo ezithile zemakethe, noma ngabe okwenqwaba encane noma ukukhiqizwa kwezinga elikhulu.

Imishini yokushisela i-can body ezenzakalelayo inikeza izinzuzo eziningi ezithuthukisa ukusebenza kahle, ukunciphisa izindleko, kanye nokuthuthukisa ikhwalithi yomkhiqizo, okuwenza abe yingxenye ebalulekile ekukhiqizeni amathini esimanje.

Ngemva kwenqubo yokushisela, amashidi ensimbi abe engaphansi kokusikwa ukuze akhiqize imicu emincane ezokwakha imizimba eyi-cylindrical. Imimese yokusika i-tinplate ibalulekile kulesi sinyathelo, ukusika amashidi ensimbi ngokunemba okuqondile. Ikhwalithi yale mimese, evame ukwenziwa ngezinto ezisezingeni eliphezulu njenge-carbide, ithinta ngokuqondile ukunemba kwenqubo yokusika kanye nekhwalithi iyonke yemizimba yamathini. Izinkampani ezifana ne-Huxin Cemented Carbide zisebenza ngokukhethekile ekukhiqizeni lezi zinsimbi ze-carbide, ezaziwa ngokuba bukhali, ukumelana nokugqoka, nokuphila isikhathi eside.

Ngokuhlangene, lobu buchwepheshe bulula inqubo yokukhiqiza amathani, okuvumela abakhiqizi ukuthi bakhiqize amathini ekhwalithi ephezulu ngesivinini esisheshayo. Njengoba isidingo sabathengi sokupakishwa okuthembekile nokusimeme sikhula, imboni iyaqhubeka nokutshala imali emishinini esezingeni eliphezulu eqinisekisa ukusebenza kahle nokunemba. Kusukela ekushiseleni kuye ekusikeni nasekusikeni, ukusetshenziswa kwemishini ethuthukisiwe ekwenziweni kwamathini kuvula indlela yenkathi entsha yezixazululo zokupakisha.

China umhlinzeki oholayo weIzingcezu ezi-3 Umshini Wokwenza Ithini LethinifuthiUmshini Wokwenza I-Aerosol Can.

I-Changtai Intelligent Equipment Co., Ltd.iyifektri ye-Can Making Machine enolwazi.Kuhlanganisa ukuhlukanisa, ukubumba, ukugoqa, ukupheqa, ukubethela nokuthunga, Amasistimu ethu okwenza amasistimu afaka i-modularity ephezulu kanye nekhono lokucubungula futhi afanelekele izinhlelo eziningi ezahlukene,

Ngokusebenza kabusha okusheshayo, okulula, ahlanganisa ukukhiqiza okuphezulu kakhulu nekhwalithi ephezulu yomkhiqizo, kuyilapho enikeza amazinga aphezulu okuphepha kanye nokuvikela okusebenzayo kwama-opharetha.

Yazi okwengeziwe

Ukuze uthole okwengeziwe ngezintengo namasevisi, sicela uchofoze lapha>>>Xhumana nathi

--------

Ukuze uthole okwengeziwe mayelana neNkampani yethu, sicela uchofoze lapha >>>Mayelana NATHI

--------

Ukuze uthole okwengeziwe ngephothifoliyo yethu, sicela uchofoze lapha>>>Imikhiqizo Yethu

--------

Ukwazi okwengeziwe nge-AfterSales yethu nabanye Abantu baphinde babuze imibuzo, sicela uchofoze lapha>>>FAQ

--------

Buka imikhiqizo > > >Isixhumanisi: Ingakwazi ukwenza imishini...

Isikhathi sokuthumela: Jun-12-2025