Umugqa wokukhiqiza ithini elingunxande ozenzakalelayo ongu-1-5L

Umugqa wokukhiqiza ithini elingunxande ozenzakalelayo ongu-1-5L

Ividiyo Yokukhiqiza

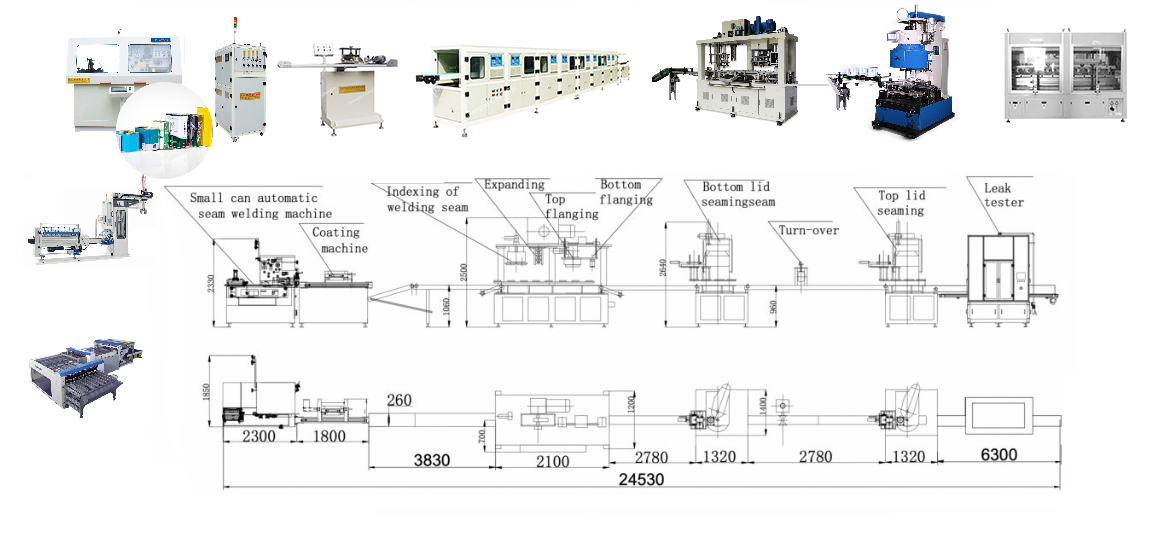

Iumugqa wokukhiqiza ithini elingunxande ongu-1-5L ozenzakalelayoifanele ukukhiqizwa ngokuzenzakalela kwethini elingunxande elingu-1-5L.

Imishiniukwenza ngezifisongokwesayizi wamathini akho kanye nezidingo zobuchwepheshe, njengohlelo lokudlulisa, uhlelo lokuthutha kanye nolwe-palletizing lungakhanselwa.

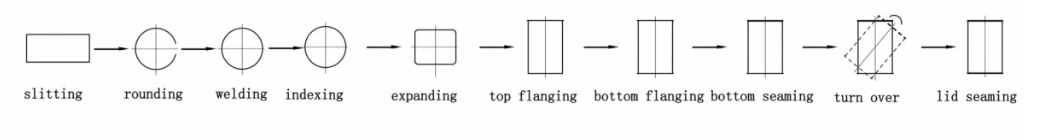

Inqubo yokusebenza elula

1. Bekaizinto zomzimba zethini ezisikiweEtafuleni lokudla lomshini wokushisela ozenzakalelayo, Munca ngama-vacuum suckers, thumela ama-tin blanks ku-feeding roller ngayinye ngayinye. Nge-feed roller, i-single tin blank inikwa i-rounding roller ukuze iqhube inqubo yokuzungeza, bese inikezwa indlela yokwenza i-rounding ukuze yenze i-rounding.

2. Umzimba uphakelwa ukumelanaumshini wokushiselafuthi wenze ukushisela ngemva kokubekwa kahle.

3. Ngemva kokushisela, umzimba wethini ufakwa ngokuzenzakalelayo ku-rotary magnetic conveyor yeumshini wokumbozakwengubo yangaphandle, ingubo yangaphakathi noma i-powder yangaphakathi, okuncike ku-izidingo ezahlukene zamakhasimendeIsetshenziswa kakhulu ukuvimbelaumugqa womthungo wokushisela ohlangothiniekuvezweni emoyeni nasekugqwaleni.

4. Umzimba wethini ube usuphakelwa omncaneumshini wokuhlanganisa ithini elingunxande, futhi umzimba wethini usesimweni sokuma udlula ku-conveyor emile. Ufakwa esiteshini sokuqala sokufaka umthungo wokuwelda ohlangothini ozenzakalelayo ngama-clamp.

5. Isiteshi sesibiliisikwele esinwebekayoUma umzimba wethini usesikhundleni, kuthreyi yokuphakamisa umzimba wethini elawulwa yi-servo motor, futhi umzimba wethini uthunyelwa yileli threyi yokuphakamisa ku-mold enwebekayo yesikwele ukuze kwenziwe ukwandiswa kwesikwele.

6. Isiteshi sesithathu ukwenzaukugoqa umzimba ongezansi.Ukuvuleka okuphansi: ithini lizothunyelwa esikhumbeni sokuvuleka esiphansi esilele engxenyeni engenhla yomshini ngokuphakamisa ithileyi ukuze likwenze.

7. Isiteshi sesine ukwenzaukugoqa okuphezulu komzimba wethini.Ukuvuleka okuphezulu: isilinda esiphezulu sizocindezela umzimba wethini endaweni yokubumba okuphezulu ukuze sikwenze. Ukuvuleka komzimba wethini eliphezulu nelingaphansi kuqhutshwa ngamasilinda amane.

8. Isiteshi sesihlanu singuukuthungwa phansi okuzenzakalelayoNgemva kwezinyathelo ezinhlanu ezingenhla, umzimba wethini uzobuyiselwa emuva phezulu naphansi nge-body turner bese kwenziwa i-top seaming, le nqubo ifana nenqubo yokuthunga engezansi.

Okokugcina, ithini eliqediwe liphakelwa yi-conveyor ukuzeisiteshi sokuhlola ukuvuza okuzenzakalelayoNgemva kokuhlolwa okunembile komthombo womoya, imikhiqizo engafaneleki iyatholwa bese isunduzelwa endaweni eqondile, futhi imikhiqizo efanelekile izofika ebhentshini lokusebenzela lokupakisha ukuze kufakwe okokugcina.

Ukwakheka kanye ne-Tech-Parameter

Iumshini wokusika insimbi we-duplex or umshini wokusika ishidi le-tinplateingenye yezingxenye ezibaluleke kakhulu zemishini ku-umugqa wokukhiqiza ithini onezingcezu ezintathu.iyisiteshi sokuqala somugqa wokwenza amathini. Isetshenziselwa ukusika ishidi le-tinplate noma ishidi lensimbi engagqwali njengezikhala zomzimba zethini ezinobukhulu obudingekayo noma imichilo yeziphetho zamathini. I-duplex slitter esezingeni eliphezulu iyintuthuko yokuqala esixazululweni esifanele sefektri yokupakisha insimbi. Iguquguqukayo, Iqondile futhi Iqinile yizidingo eziyisisekelo ze-duplex slitter.

I-slitter ine-feeder, i-shear, ibhokisi lokulawula likagesi, i-vacuum pump, i-loader kanye ne-sharpener. I-slitter enemisebenzi eminingi iyakwazi ukuguquguquka futhi ingaphakela ngokuzenzakalelayo,ukusika okuqondile, okuvundlile ngokuzenzakalelayo, ukutholwa kwe-duplex kanye nokubalwa kwe-electromagnetism.

Ngamafuphi, i-automatic duplex slitter isebenza kanje:

1. Ukuphakelwa Kwamashidi Okuzenzakalelayo

2. Ukusika Okuqondile, Ukuguqula kanye nokubeka, Ukusika Okuvundlile

3. Ukuqoqa nokubeka izinto ndawonye

| Ibanga lokuvama | 120-320HZ | Isivinini sokushisela | 6-36m/min |

| Amandla okukhiqiza | Amathini angu-30-200/umzuzu | Ububanzi bekhani | Φ52-Φ99mm&Φ65-Φ180mm |

| Ububanzi bokuphakama kwethini | 55-320mm | Izinto ezisebenzayo | I-Tinplate, esekelwe ensimbini, ipuleti le-Chrome |

| Ubukhulu bezinto ezibonakalayo | 0.16~0.35mm | Ububanzi bentambo yethusi obusebenzayo | Φ1.38mm ,Φ1.5mm |

| Amanzi okupholisa | Izinga Lokushisa: ≤20℃ Ingcindezi: 0.4-0.5Mpa Ukugeleza: 10L/min | ||

| Amandla | 40KVA | Ubukhulu (L*W*H) | 1750*1500*1800mm |

| Isisindo sengqikithi | 1800Kg | Impuphu | 380V±5% 50Hz |

Iumshini wokushisela umzimba wethini ozenzakalelayoiphakathi kwengqikithi yanoma yimuphi umugqa wokukhiqiza amathini anezingcezu ezintathu. Yakha umzimba ungena ngaphakathi kwawoisimo esiyisisekelofuthiishibiliza ukugoqana komthungo. Umgomo wethu wokushisela we-Superwima udinga ukunqwabelana okuncane kakhulu kwezingxenye ezimbalwa kweshumi zemilimitha. Ukulawulwa okuhle komsinga wokushisela kuhlanganiswe nengcindezi ehambisana kahle nokugqagqana. Kusukela kwasungulwa isizukulwane esisha sabashiseli, amakhasimende emhlabeni wonke namuhla aqinisekisile ukwaneliseka kwawo okukhulu ngokuthembeka komshini okuvelele nokuphezulu kuhlanganiswe ne-ezomnothokanyeukukhiqizwa okuphumelelayoKubekwe izindinganiso ezintsha zezimboni ekwakhiweni kwama-canbodies emhlabeni jikelele.

Uhlelo lokumboza

Uhlelo lokumboza ngempuphu lungomunye wemikhiqizo yokumboza ngempuphu eyethulwe yiChangtai Company. Lo mshini unikezelwe kubuchwepheshe bokumboza ngesifutho bokushisela amathangi kwabakhiqizi bamathini.

| Imodeli | I-CTPC-2 | I-Voltage kanye nemvamisa | 380V 3L+1N+PE |

| Isivinini sokukhiqiza | 5-60m/min | Ukusetshenziswa kwempuphu | 8-10mm & 10-20mm |

| Ukusetshenziswa komoya | 0.6Mpa | Ububanzi bomzimba wekhabhini | D50-200mm D80-400mm |

| Isidingo somoya | 100-200L/min | Ukusetshenziswa kwamandla | 2.8KW |

| Ubukhulu bomshini | 1080*720*1820mm | Isisindo esikhulu | 300kg |

Uhlelo lokumboza ngempuphu lungomunye wemikhiqizo yokumboza ngempuphu eyethulwe yiChangtai Company. Lo mshini unikezelwe kubuchwepheshe bokumboza ngesifutho bokushisela amathangi kwabakhiqizi bamathini.

| Ibanga lokuphakama kwekhani | 50-600mm | Ububanzi bekhani | 52-400mm |

| Isivinini se-roller | 5-30m/min | Uhlobo lokumboza | Ukugqoka okugoqekayo |

| Ububanzi be-lacquer | 8-15mm 10-20mm | Ukunikezwa Okuyinhloko Nomthwalo Wamanje | 220V 0.5 KW |

| Ukusetshenziswa komoya | 0.6Mpa 20L/min | Ubukhulu bomshini kanye nesisindo esiphelele | 2100*720*1520MM300kg |

Inkampani yethu isebenzisa ubuchwepheshe obuthuthukisiwe bokumboza ngempuphu, okwenza isakhiwo esisha somshini, ukuthembeka okuphezulu kohlelo, ukusebenza okulula, ukusebenza okubanzi kanye nesilinganiso esiphezulu sokusebenza nentengo. Kanye nokusetshenziswa kwezingxenye zokulawula ezithembekile, kanye ne-terminal yokulawula ukuthinta nezinye izingxenye, okwenza uhlelo luzinze futhi luthembeke kakhudlwana.

Umshini wokumboza i-powder usebenzisa ugesi ongashintshi ukufafaza i-plastic powder ku-weld yomzimba wethangi, futhi i-solid powder iyancibilika futhi yomiswe ngokufudumeza kuhhavini ukuze kwakheke ungqimba lwefilimu yokuvikela yepulasitiki (i-polyester noma i-epoxy resin) ku-weld. Ngenxa yokuthi i-powder ingamboza ngokuphelele nangokulinganayo ama-burrs kanye nezindawo eziphakeme neziphansi ku-weld ngokwesimo esithile se-weld ngomgomo wokumuncwa kwe-electrostatic ngesikhathi sokufafaza, ingavikela kahle i-weld ekugqwaleni kokuqukethwe;

Ngesikhathi esifanayo, ngenxa yokuthi i-powder yepulasitiki inokumelana okukhulu nokugqwala ezinyibilikisini zamakhemikhali ezahlukahlukene kanye ne-sulfur, i-asidi kanye namaprotheni amaningi ekudleni, i-powder spray ifaneleka kokuqukethwe okuhlukahlukene okuhlukahlukene; Futhi ngenxa yokuthi i-powder eningi ngemva kokufutha i-powder isebenzisa isimiso sokuvuselela nokuphinda isetshenziswe, izinga lokusetshenziswa kwe-powder liphezulu, futhi iyisinqumo esihle kakhulu sokuvikela ukushintshwa kwe-weld okwamanje.

Uyini umshini wokumboza ngomthungo kanye nokusetshenziswa kwawo?

Ngemva kokushisela, ukuthunga kwangaphakathi nangaphandle kufanele kugqokwe ngesendlalelo esivikelayo esiqinile, khona-ke umthungo wokushisela ngeke ugqwale. Umshini wokumboza umthungo we-lacquer omanzi uhlanganiswa ngokungahleliwe ngezidingo ezahlukahlukene, umthungo ongaphakathi ungaba yi-roller coating noma i-spray coating, umthungo ongaphandle ungaba yi-roller coating, i-spray coating noma i-drop coating. Umshini wokumboza umthungo oseceleni uguquguqukayo kakhulu ekumbozeni umthungo wamathini okudla, amathini okuphuza kanye namathini e-aerosol kanye nezitsha zokupakisha zezimboni. I-can coater kulula ukuyilungisa futhi i-lacquer isetshenziswa kancane.

Ngokusho kwesixazululo sokumboza, umshini wokumboza i-lacquer uyaguquguquka, wokumboza ngaphakathi, Singawuklama njengopende wokufutha noma we-roller, wokumboza ngaphandle, kungaba upende we-roller noma we-drop. Umenzi wethini angakhetha idivayisi efanelekile yokuhlanganiswa kwamahhala.

Isicelo:

Umshini wokumboza ungasetshenziswa kabanzi embonini yokukhiqiza amathini ensimbi, ukuvikela umthungo ohlangothini ohlanganisiwe ekugqwaleni nasekugqwaleni. Umshini ulungele:

1. Umugqa ojwayelekile ungenza

2. Ukwenza ithini lokudla elinezingcezu ezintathu

3. Ukwenza ithini le-aerosol

4. Ukwenza ibhakede eliyindilinga noma elekhemikhali

5. Ukwenza ibhakede lokugoqa noma ibhakede lokuncibilikisa

6. Ukwenza ithini lokupenda

Imishini yokufutha edlulisa idlala indima ebalulekile embonini yokukhiqiza amathini. Ngokuhlanganisa okuzenzakalelayo, amakhono okufutha anemisebenzi eminingi, umklamo osebenzisa amandla amaningi, ukulawulwa kwekhwalithi, kanye nobuchwepheshe bokufutha obusha, le mishini inikeza izixazululo zokukhiqiza ezisebenzayo, ezithembekile, nezincintisanayo kubakhiqizi bamatithini.

Uhlelo lokupholisa olungeniswayo noma umshini wokomisa wokushisela ithini nomzimba kuyingxenye ebalulekile yomugqa womshini wokukhiqiza wokukhiqiza amathini okudla, iziphuzo, kanye nobisi oluyimpuphu. Lusetshenziselwa ukomisa amathini ngemva kwenqubo yokumboza noma yokuphrinta, ukuqinisekisa ukuqiniswa okufanele nokunamathela kwezinto ezisetshenziswayo.

Ukukhiqiza kanye nekhwalithi iyonke yenqubo yokukhiqiza amathini. Ngemuva kohlelo lwayo lokuphilisa, amakhono okomisa asebenzayo, ukulawulwa kokushisa okunembile, ukwakheka okufushane, ukusebenza kahle kwamandla, kanye nezici zokuphepha.

| Isivinini se-Conveyor | 5-30m/min | Ububanzi bekhani | 52-180mm |

| Uhlobo lwe-Conveyor | Idrayivu ye-flat chain | Ikhoyili yokupholisa. | Akudingi amanzi/umoya |

| Ukushisa okusebenzayo | 800mm*6(30cpm) | Ukunikezwa Okuyinhloko Nomthwalo Wamanje | 380V+N>10KVA |

| Uhlobo lokushisa | Ukungeniswa | Ibanga lokuzwa | 5-20MM |

| Ukushisa Okuphezulu | 1KW*6 (isethi yokushisa) | Iphuzu lokungeniswa | 40MM |

| Ukusetha imvamisa | 80KHz+-10 KHz | Isikhathi sokungeniswa | 25Sec(410mmH,40CPM) |

| Ukuvikela imisebe ye-Electro. | Imbozwe ngonogada bokuphepha | Isikhathi sokuvuka (MAX) | Ibanga 5mm 6sec&280℃ |

| Ubukhulu (L*W*H) | 6300*700*1420mm | Isisindo sengqikithi | 850KG |

I-Changtai inezinhlelo zokulungisa eziklanyelwe ukuqinisa ungqimba lokuvikela umthungo ngempumelelo. Ngemva nje kokusebenzisa ungqimba lokuvikela umthungo we-lacquer noma we-powder, i-canbody iya ekwelashweni kokushisa. Sithuthukise izinhlelo zokushisa ezithuthukisiwe eziqhutshwa yigesi noma ze-induction ezinokulawulwa kokushisa okuzenzakalelayo kanye namabhande okuhambisa alungisekayo ngesivinini. Zombili izinhlelo zokushisa zitholakala ngendlela eqondile noma ngesimo se-U.

Ukwakha nokuhlanganisa i-canbody

Umshini Wokuhlanganisa I-Canbody

| Umthamo wokukhiqiza | 30-35cpm | Ububanzi be-Can Dia. | 110-190mm |

| Ibanga lokuphakama kwekhani | 110-350mm | ukujiya | ≤0.4 |

| Amandla | 26.14kw | Ukucindezela kohlelo lomoya: | 0.3-0.5Mpa |

| Usayizi wokuthutha umzimba oqonde phezulu | 2250*230*920mm | Usayizi wokuthutha ongaphakathi | 1580*260*920mm |

| Usayizi womshini ohlanganisiwe | 2100*1500*2340mm | Isisindo sengqikithi | 4T |

| Ubukhulu bekhabhathi kagesi | 700*450*1700mm | ||

Umshini wokuthunga ithini ozenzakalelayo

| umthamo wokukhiqiza | 35cpm |

| ububanzi obuvundlile | 50-190m |

| ububanzi bokuphakama kwethini | 80-350mm |

| ukujiya | ≤0.35mm |

| amandla aphelele | 5.13KW*2 |

| ingcindezi yesistimu yomoya: | 0.5Mpa |

| usayizi we-conveyor yesigaba esingaphambili | (2740*260*880mm)*2 |

| usayizi womshini wokuthunga | (1100*310*950mm)*2 |

| isisindo somshini wokuthunga | 2.5T*2 |

Umshini wethu wokulungisa i-Can kanye nomshini wokwakha isimo somzimba we-can kufanelekile ezinhlotsheni eziningi zokusebenza, okuhlanganisa ukuhlukanisa, ukubumba, ukugoqa intamo, ukufuqa, ukufaka ubuhlalu kanye nokuthunga. Ngokulungisa kabusha okusheshayo nokulula, bahlanganisa umkhiqizo ophezulu kakhulu nekhwalithi ephezulu yomkhiqizo, ngenkathi benikeza amazinga aphezulu okuphepha kanye nokuvikelwa okusebenzayo kwabasebenzi.

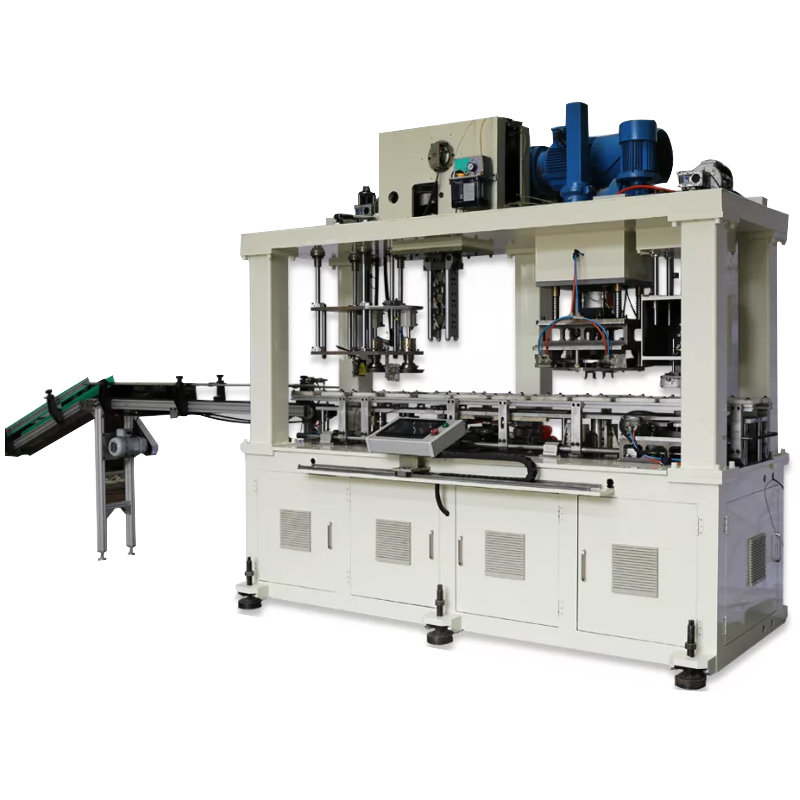

Ukwenza Amathini Ethini, Umshini Wokuhlanganisa,

Ihlanganisa imisebenzi ye-Flanging, Beading kanye ne-Seaming enqubweni eyodwa.

Umshini wokuhlanganisa i-flanging, beading, kanye ne-thunging uhlinzeka ngokusebenza okuhlanganisiwe okunemisebenzi eminingi ekukhiqizeni amathini ethini. Ungenza izinqubo ze-flanging, beading, kanye ne-thunging, uhlanganise izinyathelo eziningi zibe umshini owodwa, okuthuthukisa kakhulu ukusebenza kahle kokukhiqiza kanye nokusebenza kahle.

Umhloli wokuvuza

| Ububanzi bevolumu yomkhiqizo obutholiwe | 1-5L |

| Umfutho womoya wemishini | Ibha engu-4-6 |

| Hlola ingcindezi | 10-15Kpa |

| Ukunemba kokutholwa | 0.17mm |

| Isivinini sokuthola | 30PCS/imizuzu |

| Isisindo Sedivayisi | 1500KG |

| Ubukhulu (L*W*H) | 3200mm*950mm*2200mm |

| Amandla okufaka | 380v/50HZ |

Sihlinzeka ngabahloli bokuvuza babo bonke osayizi nezimo zamathini kanye nama-pail nama-drum abo bonke osayizi.

Uma izitsha zensimbi noma izitsha zepulasitiki ziqedwa ngomugqa wokwenza amathini, izitsha zifakwa emshinini wokuhlola ukuvuza, ovame ukubizwa ngokuthi umhloli wethini, umhloli wethini noma umhloli wedramu kuye ngento etholakele. Umhloli wokuvuza uhlola futhi athole izitsha ngomoya, izitsha zingondliwa njengomugqa noma ngokujikeleza. Kumathini noma amathini ajwayelekile, isivinini somugqa wokukhiqiza amathini asiphezulu kangako, kungcono ukusebenzisa ukwakheka komhloli wokuvuza okusemgqeni njengomugqa, futhi kumathini e-aerosol noma ekamelweni elincane, kungcono ukusebenzisa umshini wokuhlola amathini ojikelezayo.

Uhlelo lokufaka i-Pallet

| Ukuphakama komsebenzi usayizi wephalethi ofanele | 2400mm |

| usayizi wephalethi ofanele | 1100mm × 1400mm;1000mm x 1200mm |

| Amandla okukhiqiza | Amathini angu-300~1500/min |

| Usayizi wethini osebenzayo | Ububanzi 50mm~153mm, ukuphakama: 50mm~270mm |

| Umkhiqizo osebenzayo | Zonke izinhlobo zethini le-tinplate, ibhodlela lengilazi kanye nebhodlela lepulasitiki |

| Ubukhulu | Ubude 15000mm (ngaphandle kwefilimu yokusonga) × ububanzi 3000mm × ukuphakama 3900mm |

| Ukunikezwa kwamandla kagesi | 3×380V 7KW |

Umugqa wokukhiqiza ithini uvame ukuphela nge-palletizer. Umugqa wokuhlanganisa amabhakede ungenziwa ngokwezifiso, okuzoqinisekisa ukuthi izitaki zingafakwa emaphalethini ezinyathelweni ezilandelayo. Amanye amakhasimende athola abasebenzi ukuthi benze lo msebenzi.

Ukwenza ubuciko ngethini

1-5Lunxande ishadi eligeleza ngethini

Iphrofayela Yenkampani

Yaqalwa ngo-2007, iChengdu Changtai ibilokhu izinikele ekwenzeni imishini yamathini iminyaka engama-20, manje isibe yinkampani yezobuchwepheshe ethuthukisiwe kazwelonke enamalungelo obunikazi okusungula angaphezu kweshumi. Sineqembu elisezingeni eliphezulu lonjiniyela abanekhono kanye nochwepheshe abanolwazi olubanzi ekwenzeni amathini amathini amathathu kanye nokucwaninga nokusebenzisa imishini yokukhanya, yedijithali, kagesi emishinini yokufaka amathini. Ngesitifiketi se-ISO9001, i-SGS kanye ne-BV, yenza kube uphawu lwemishini yokukhiqiza amathini oludumile eShayina.

Xhumana ukuze uthole imibuzo ngemishini