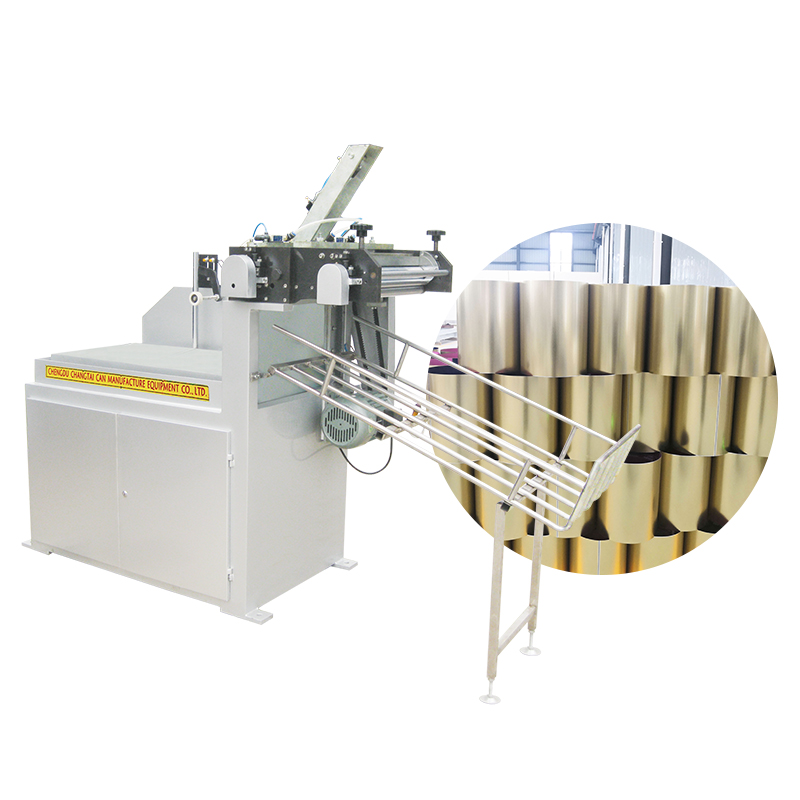

Ingabe ukwenza umshini powder uhlelo for metal can round can square can

Ingabe ukwenza umshini powder uhlelo for metal can round can square can

Imingcele Yezobuchwepheshe

| Imodeli | I-CTPC-2 |

| Isivinini Sokukhiqiza | 5-60m/min |

| Ububanzi bempushana | 8-10mm 10-20mm |

| Can Body range | 50-200mm 80-400mm |

| Okubalulekile | Ipuleti le-tinplate/insimbi-based/chrome |

| Ukunikezwa kwamandla kagesi | 380V 3L+1N+PE |

| Ukusetshenziswa komoya | 100-200L/min |

| Izilinganiso Zomshini | 1080*720*1820 |

| Isisindo | 300kg |

1. Ukusetshenziswa komoya ocindezelwe kuphansi kakhulu, kuphela ukulawula umoya, umkhawulo ngu-150L.

2. I-powder fluidization emgqonyeni we-powder yamukela umoya oshisayo ocindezelayo ophezulu okhishwe yi-fan ephezulu yokucindezela okungeniswa kwamanye amazwe njengegesi ye-fluidization yokushisa nokushisa i-powder emgqonyeni.Ngakolunye uhlangothi, igcina umoya ocindezelweyo (okulingana nokugcina i-compressor engu-5.5KW), ngakolunye uhlangothi, ixazulula ngokuphumelelayo inkinga yomswakama ku-powder.

3. Impushana etholiwe idlula esiteshini sokutakula esifakwe uzibuthe oqinile ukuze isuse ukungcola kwensimbi okufana nama-burrs akhiqizwa ngokushisela, bese ingena esikrinini esidlikizayo kanye nempushana entsha ukuze ihlolwe ukuze kukhishwe ukungcola okungeyona insimbi kumpushana, futhi hlanza impushana entsha.Ama-agglomerate ku-powder ayachotshozwa.

4. I-fan exhaust yokutakula isebenzisa izakhi zokuhlunga ze-titanium alloy eziyi-8, ezihlala isikhathi eside, futhi isici sokuhlunga ngasinye sihlukaniswe ngeshubhu elivikelayo.Lapho isici sokuhlunga sihlanzwa, singehlisa impushana ephephukayo iye kokunye okungu-7 okusalulama futhi kuyakhathaza.Umthelela wesici sokuhlunga kuphela, futhi unciphise ngempumelelo umthelela wesici sesihlungi kumbobo yokutakula phakathi nokuhlanza ngokubuyisela emuva.

5. Ukuphephetha ngemuva kwesihlungi kusebenzisa isakhiwo esiyingqayizivele.Uma isici sokuhlunga siphephuka, ukuvulwa kwesici sokuhlunga kungavalwa, igesi evuthela emuva ingasetshenziswa ngokuphumelelayo, futhi umthelela wokubuyisela ungancishiswa.Ibhakede lempushana lifakwe injini edlidlizayo, enciphisa ithuba lokuthi impushana inamathele kusici sokuhlunga.

6. Ngemuva kokufafaza kwe-powder ngayinye, umshini ungasula ngokuzenzakalelayo i-powder esele epayipini lokufafaza i-powder ukuze kuqedwe ukuqoqwa nokuvinjelwa kwe-powder esele epayipini le-powder, okuzobangela ukufafaza kwe-powder okungalingani kwethangi elilandelayo.

7. Uma isebenza ngokuzenzakalelayo, izobambezeleka ngokuzenzakalelayo lapho ima (isikhathi singasethwa ngokunganaki) ukuhlanza yonke impushana eqoqiwe epayipini.

8. Ukuze uvimbele